Founded in 1958, Nan-Ya Plastics Corporation (NYP) is one of the world's largest manufactures in terms of production capacity, with more than 10,000 employees. NYP has long been committed to Industry 4.0 practices, aiming at sustainable business development as well as social wealth and prosperity.

Project Intention

NYP wanted to link all its manufacturing data across multiple sites to its control center, enabling around-the-clock real-time monitoring of data. By collecting production line operation status and machine condition data, NYP can enhance its overall equipment effectiveness, shorten its time to market, and make its business environmentally friendly.

Challenges and Requirements

Operating in the plastic manufacturing industry for more than 50 years, NYP has many existing machines and wired network infrastructure that needed to be integrated. However, the company did not initially plan to install wired infrastructure between buildings, which made each factory building work in isolation. Connecting each isolated network system without discarding current equipment became the major focus of this project.

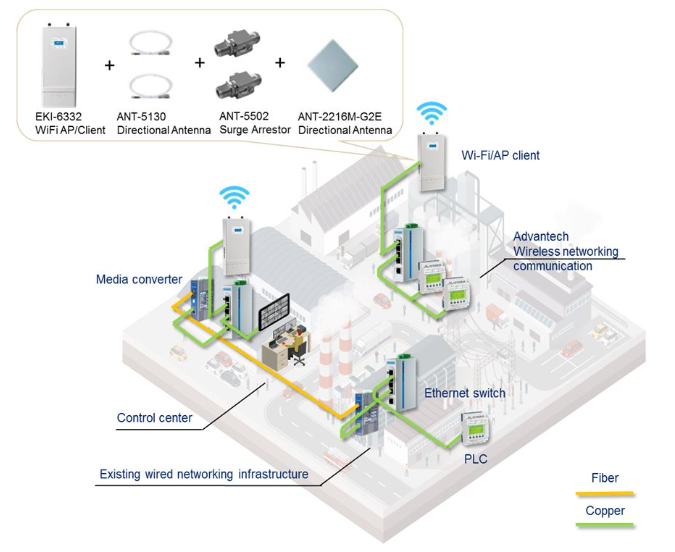

To become a future-proof, upgrade-ready manufacturer, NYP was determined to use a wireless bridge solution to establish inter building connectivity so that the central control room could monitor all data acquired from dozens of PLCs. For this, there are a few requirements and restrictions that required consideration.

- Wi-Fi access points (APs) to be placed on top of each manufacturing building, all of which ranged from one to seven floors in height

- Transmission distances ranged from 90 ft. to 550 ft.

- High-level wireless signal and device security to prevent attacks from hackers

- High IP rating to protect against dust and humidity

Solution

Each factory site has its own Ethernet switch, which is connected to PLCs for data acquisition and transmission. The acquired data is sent via a wireless AP/client to the control center, where operators can monitor and manage the factory status and performance. Since some factories already have a fiber network deployed, a media converter was adopted to convert from copper to fiber, allowing for longer distance data transmission.

Features, Advantages and Benefits

Ruggedized

- IP55 rating against dust and moisture

- Lightning proof

Secured

- WPA2 wireless encryption and authentication

- Access control + lock to AP MAC to prevent intrusion from unauthorized Wi-Fi devices

Upgrade-Ready

- Wireless deployment allows for instant device add-in or removal

- High transmission distance ranges from 90 ft. to 550 ft.

Advantech's EKI-6332, an industrial Wi-Fi AP client, has an IP55 rating, meaning that it can operate under high-humidity conditions. The software supports WPA2 wireless encryption and authentication, access control, and lock to AP MAC, blocking unidentified users and unauthorized Wi-Fi devices from accessing confidential data. The wireless deployment and long transmission distance ensure that NYP is always prepared for future upgrades, which is critical considering the high probability of campus reinforcement and business expansion.

Conclusion

Advantech products successfully provided NYP an integration solution that formed the previously isolated factories into a complete network system. The enhanced control, monitoring, and management network infrastructure has assisted NYP in realizing its position as a company focused on future sustainability.

This article has been adapted from an Advantech Industrial IoT Blog post. Click here to view the original post.