In-Vehicle Computer Leads the Way of Autonomous Delivery

Overview

According to a McKinsey research, e-commerce has grown two to five times faster than before the pandemic across different countries. The soaring demands for shipment delivery have resulted in a severe backlog at many seaports and a massive shortage of drivers in road freight, entailing the need for smarter logistics and delivery solutions to solve problems and reduce costs. Autonomous delivery is deemed as one of the answers, which could bring seismic changes to the world of retail and become a driving force for the development of next-generation transportation systems.

Our customer is one of the world's most remarkable forerunners in exploring autonomous delivery and intelligent logistics, who has employed state-of-the-art driverless technology and cargo robotics in developing autonomous electric vehicles for last- and middle-mile multi-stop delivery services. Their cars run on public roads with no cabin, no steering, no pedals, no driver and no workers, ensuring maximum volumetric and energy efficiency with minimal operational costs.

Their revolutionary vehicles are realized with the joined support of Neousys' high-performance in-vehicle controller Neousys VTC Series that delivers compelling processing power, fast data communication capabilities, and rugged construction.

Challenges

Ultra-low latency in data transmission ensuring safety and reliability

Autonomous driving technology is composed of self-driving software, AI algorithms, sensors (e.g., cameras, LiDAR and radar), ECUs and other hardware components, working in concert with each other, which needs robust in-vehicle communications among all the things and fastest wireless vehicle-to-vehicle (V2V) and vehicle-to-everything (V2X) communications to ensure highest situational awareness and safety.

Our customer also has developed a personnel remote operation system that allows remote supervision and control of the delivery vehicles in cases where autonomy cannot be applied. It be difficult for the conventional 4G speed of wireless communication to achieve seamless handoffs and meet latency requirements, and 5G-grade speed will be needed in such mission-critical applications with no tolerance for errors.

High computing power for real-time decision making

Automated driving and delivery practices need intense computations for real-time decision-making and responses. However, the need for high performance sometimes would contradict lower thermal envelop requirement in a robust in-vehicle fanless system, and an artful design to strike the best balance ensuring both highest performance and ruggedness will be the answer.

Ruggedness to withstand shock and vibration

An in-vehicle system needs to withstand constant shock and vibration on the road to provide reliability for 24/7 operations. This is particularly a highlight for mission-critical applications like autonomous driving which often adopts rugged designs such as fanless systems and connector reinforcements.

Solution

Based on the lessons learned from its vast field experience, our customer developed their next-generation autonomous delivery vehicles capable of operating at highway speeds, an entirely novel system combining autonomous technology, cargo robotics, remote operation, and mobile app/services.

The CoastIPC Nuvo VTC series, featuring one of the best-in-class rugged designs, rich I/O connectivity supporting 5G communication and Intel 9th/8th-Gen processing power, is deployed as the in-vehicle computer to implement data logging, gate control, process-monitoring, surveillance of goods pickup, as well as remote control via a SCADA system.

Advantages of CoastIPC VTC Series

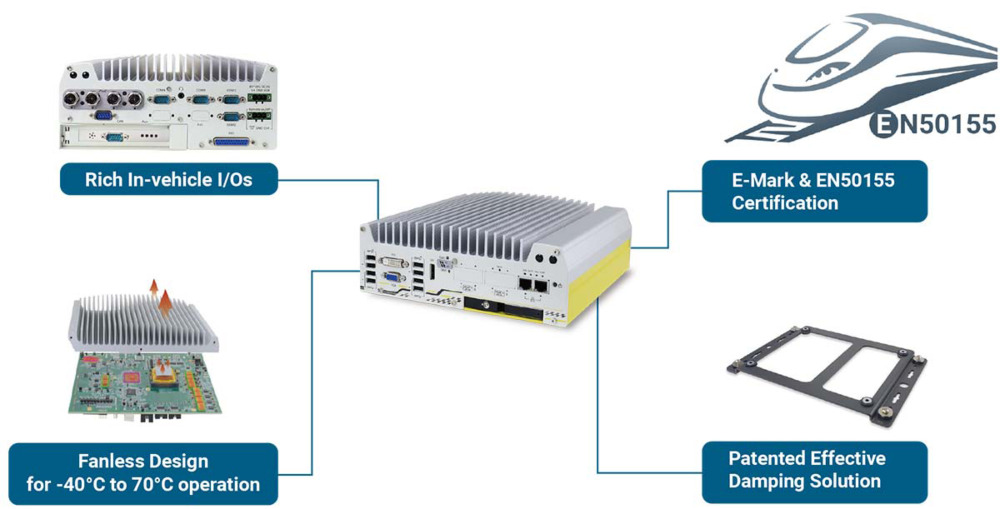

A high-performance fanless in-vehicle system providing commensurate computing power for enabling AI-based autonomous vehicles, in a compact size increasing the volumetric efficiency of our customer's vehicles.

Offers rich I/O and connectors in support of isolated CAN bus for in-vehicle communication and 5G/LTE for ultra-low latency wireless communication, as well as a wealth of peripherals and functions, including ignition control, DIO, GPS, and more.

In addition to E-Mark and EN50155 conformity, the platform also comes with a patented damping design, screw-lock connectivity to ensure reliable operations, and wide operating temperature support ranging from -40°C to 70°C to further reinforce reliability.