With the invention of the personal computer (PC), everything changed. Suddenly people and machines could do more — faster — than ever before.

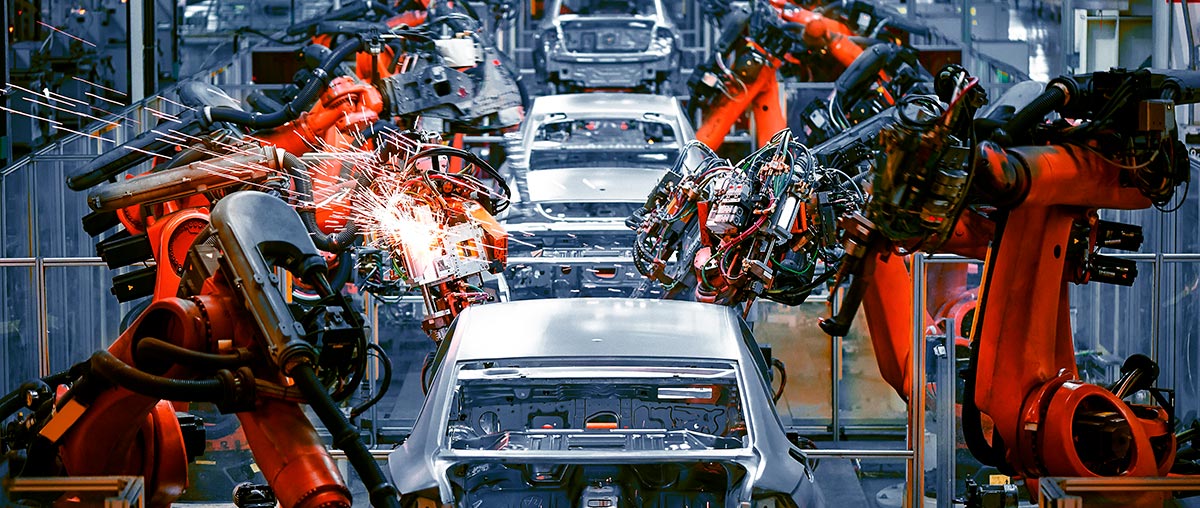

Today, it is the industrial PC that keeps the world running in smooth grooves. Industrial PCs are the brains driving the machines we depend on every day — from electric vehicles to medical diagnostic equipment. Therefore, the performance, health, and longevity of an industrial PC are critical considerations when designing the systems of the future.

While some have tried to place standard PCs in industrial environments, mission-critical applications such as industrial automation, machine learning (ML) and artificial intelligence (AI), robotics, video surveillance, and autonomous vehicles demand much more than a standard brain. Customers in these markets need consistent and scalable computers that have long lifecycles and can withstand harsh environments that ordinary computers cannot. The following describes the importance of industrial PCs, the significant parts that comprise these computers, and how smart industrial PC providers approach building such systems for scalability, longevity, and repeatability.

“Industrial PC customers need consistent and scalable computers that have long lifecycles and can withstand harsh environments that ordinary computers cannot.”

Scalability for Meeting Evolving Needs

Customers must feel confident that an industrial PC can solve problems today and adapt to future needs. For example, power requirements for a factory, an autonomous vehicle, a video analytics pole on a highway, or an AI/ML application can be moving targets. To accommodate this, reliable industrial PC providers might overengineer a product to add flexibility. Power supplies may be oversized, for instance, since customers might want to further customize the computer. For additional flexibility, computers should come with a wide range of inputs: 100 to 240 V AC on rack-mount computers and 8 to 35 V DC on fan-less units. Exceptions exist, however. Graphic processing unit (GPU) computers have a different set of requirements when it comes to power and temperature. Should your application require additional computing power, the PC provider can build GPUs into the system as well.

“Should your application require additional computing power, the PC provider can build GPUs into the system.”

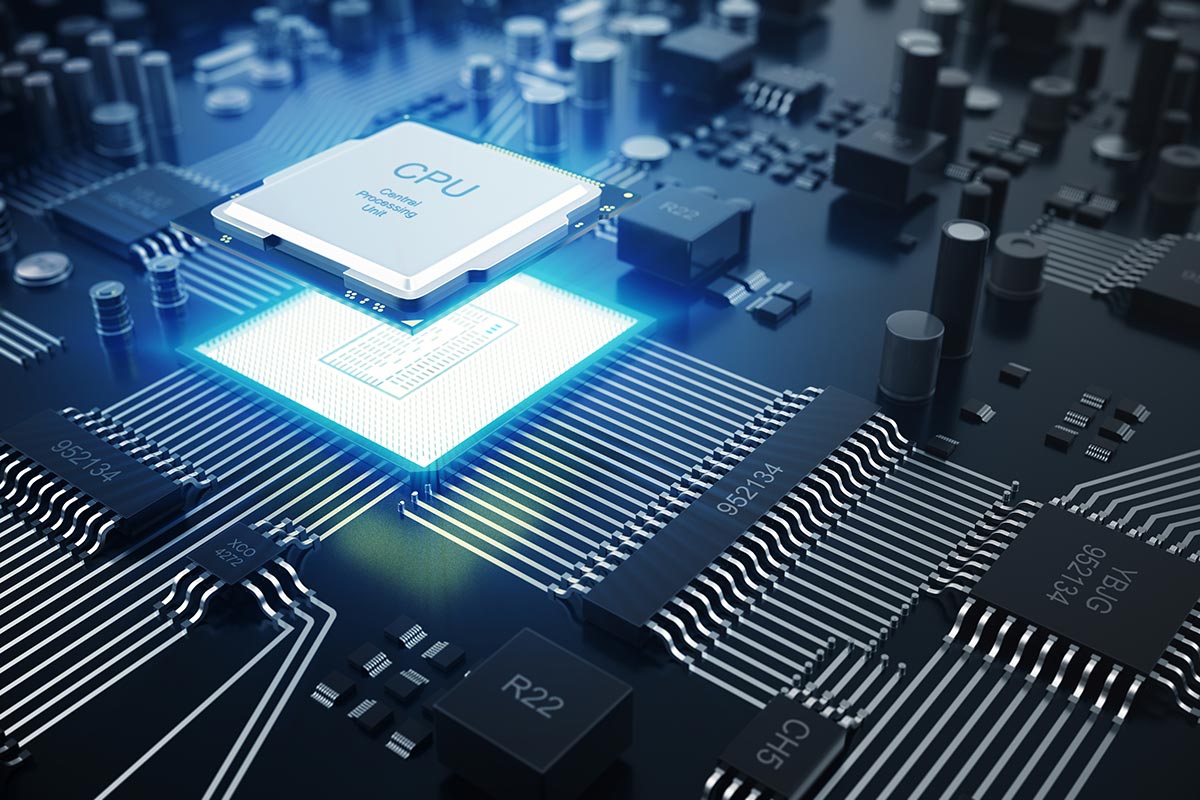

Several central processing units (CPUs) and underlying components can run at extreme temperature levels using either active cooling (fans) or passive cooling (heat sinks). In active cooling applications in industrial PCs, fans are typically oversized to compensate for potential environmental changes and the addition of third-party cards into the computer, which can generate heat. These may include 10 GigE cards, digital I/O cards, or data acquisition cards. These are just a few examples of changes or additions that industrial PCs must be able to accommodate for current and future requirements.

Longevity: Expert Users Need Expert Builds

More than anything, an industrial PC needs to promise longevity. Costly or troublesome updates and maintenance are a thorn in the side to industrial PC end users. When buying an industrial PC, customers need to know that a replacement part will bear the same identification number as the original. Subsequent orders should have consistent software and components and be built the same way. Industrial PC companies must offer customers the ability to buy the same configuration for years to come.

Desktop computers typically have a 12- to 18-month lifecycle before components start to change. When CoastIPC builds an industrial computer, it begins with CPUs on the long service lists of Intel and Advanced Micro Devices (AMD), and it can typically guarantee a CPU lifecycle with a minimum of five to seven years. With application software written around the CPU and the CPU controlling drivers for various functions, changing the CPU requires frequently rewriting the application software. This is expensive. Products with longevity that do not require constant software updates provide peace of mind to the customer, since there is less maintenance and overhead involved.

In addition to the CPU, a trustworthy PC provider should use motherboards, single boards, and backplanes with long lifecycle schedules that have gone through rigorous testing by the manufacturer. The provider should only purchase from vendors that design their own boards and control their migration path, which minimizes problems when manufacturers make small revisions to a board to compensate for a minor component obsolescence, for example. Features such as memory, storage, and Wi-Fi must all have a record of longevity, along with strict quality control and lifecycle controls, for an industrial PC provider to consider implementing them.

“Products with longevity that do not require constant software updates provide peace of mind to the customer.”

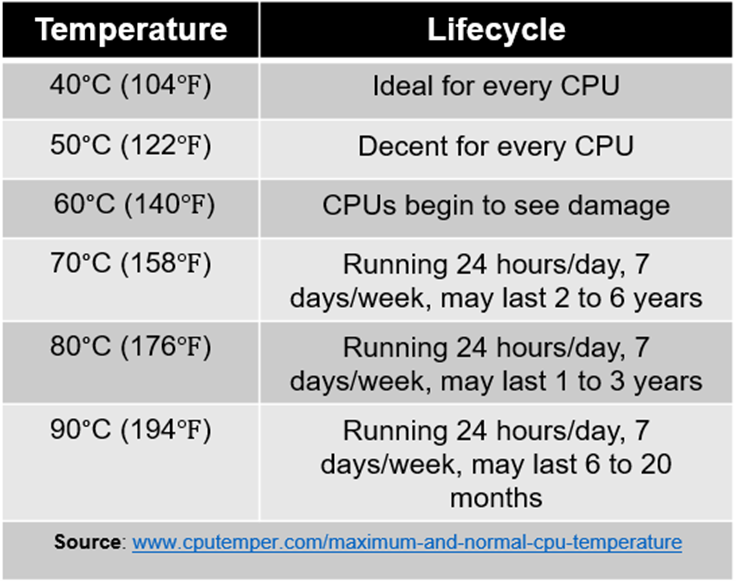

Computers can accommodate wide temperature and standard memory and drives, as required. Generally, industrial PCs are built in metal chassis, allowing them to withstand the harsh environments of industrial applications, including heat, cold, vibration, shock, and power fluctuations. It’s important to consider the environment when building an industrial PC, as extreme heat or cold can significantly impact the CPU and other components. The standard operating temperature range for a CPU is 0 to 60°C. This table provides a good estimate of the impact that extreme temperatures have on typical CPUs over time.

Repeatability: Long Lifecycles, Fewer Part Numbers

For an OEM or an end user, repeatability is always important. Being able to order a specific part and get the same configuration saves time on deployment and support, which saves money. Customers also know that by purchasing a product with a long lifecycle, they can, in a worst-case scenario, replace it with the same SKU. Ensuring that the products they buy will be sufficient for a long time allows this to happen.

When CoastIPC builds a computer, a proprietary part number is assigned to the configuration, so the customer gets the same part every time. No two companies will share the same part number! Specific part numbers can even be locked down so that no components can be substituted without customer approval, which is especially important in medical and military applications.

Scalability, longevity, and repeatability represent the three most important aspects of an industrial computer. Instead of trying to find the perfect off-the-shelf solution, let CoastIPC build the perfect industrial PC to suit your needs.

If you’d like a consultation on your industrial PC needs, please contact CoastIPC at [email protected]. You can also visit here for more information: www.coastipc.com.