Digital technology brings a host of benefits to industry, such as flexibility and decentralization. Some disadvantages are network lag and the inability to access a device or other equipment if it is powered off. This article briefly introduces some of the pros and cons of remote I/O and explains how remote on/off features add value to industry systems such as automation and machine vision applications.

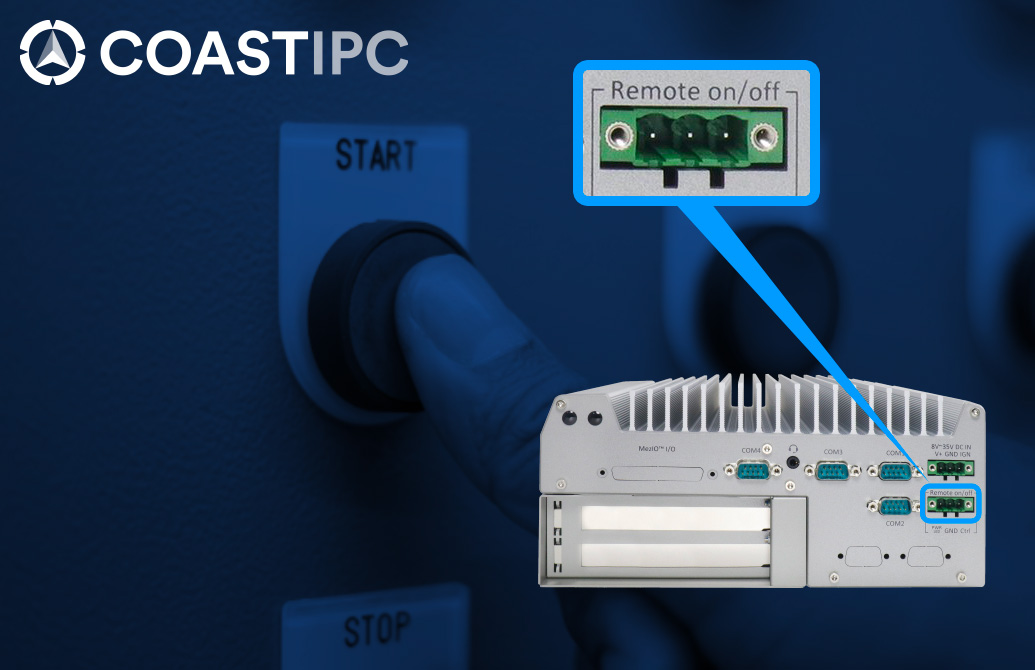

When used with a computer or server, remote on/off delivers the ability to turn equipment on and off using a remote signal from another device. The remote signal can come from a network, a timer, sensors, or user input. CoastIPC supplies industrial PCs and other devices from Advantech and Neousys Technology with multiple connections for remote on/off and more.

Driving Speed Increases at the Edge

Industries continue to innovate through digital technology with the Industrial Internet of Things (IIoT), machine vision, and smart monitoring devices. As systems and equipment become more intelligent and connected, remote features are increasingly essential for transferring large data packages reliably. When it comes to remote safety I/O and machine vision systems, fast, reliable, and redundant connections are keys to success.

Remote I/O is helping expand digital infrastructure. For example, Ethernet I/O reduces wiring and provides faster processing. However, as systems become more complex, offering remote safety, machine vision capabilities, and more, the limitations of many PLCs can slow down operations. For example, machine vision and AI applications requiring H.264/H.265 video decoding and real-time inference must transfer large amounts of data quickly. Using remote I/O on a device such as Neousys Technology’s NRU-52S – which delivers up to 21 trillion operations per second – enables more vision and AI applications.

“As systems become more complex… the limitations of many PLCs can slow down operations.”

How Remote On/Off Helps Machine Vision

Networks with limited bandwidth need fast remote processing to handle complex or large amounts of raw data close to the device, so only necessary information is sent over the network. Reducing the size or amount of information packages conserves bandwidth. Remote on/off features add great value to applications such as machine vision and connected devices that demand higher speeds and more data transfer.

Remote on/off provides options for sequencing or toggling devices on and off. Multiple sensors that are constantly sending data can create lag in a network or consume extra bandwidth. Remote on/off can shut down a device before another is powered on to limit bandwidth consumption and reduce lag.

Connected sensors can use the same remote on/off principle. For example, two devices that do not need to be on all the time, such as an IP camera and a motion detector, can use remote on/off to ensure that only one of them is running at a time. In some applications, a camera is not needed until a sensor detects a failed inspection. In this case, when the sensor triggers a fault, the system toggles from the sensor to the camera to document an image of the failure.

Why Remote On/Off Makes Sense

Security: While digital connectivity improves accessibility, it can weaken security, because devices are often left on so they can be accessed remotely. Remote on/off provides the ability to lock PCs and other devices and keep them off until they are needed. Using security profiles for remote on/off can keep devices safe without jeopardizing accessibility.

Control: When applications require control or access and a human operator is not nearby, remote on/off provides a solution. The ability to turn devices — even motors — on and off remotely, based on timers, programs, sensor inputs, or user-defined data-set timers, helps to expand technology and give greater control at a distance.

Flexibility: Technology can add flexibility to existing systems but disturbing a working infrastructure can greatly increase the time and cost associated with adding that new technology. Remote on/off can offer a brownfield or retrofit solution without the need to change existing infrastructure.

Scalability: A pilot IIoT project might succeed. However, scaling connected devices and solutions creates more complexity and consumes bandwidth. By offering the ability to run one sensor, camera, or other device at a time, and by providing control when a device is on or off, remote on/off reduces lag and improves bandwidth.

CoastIPC offers a range of industrial computers from Advantech and Neousys Technology with various connectivity options, bandwidths, speeds, and capabilities — all of which are driving industrial applications, including edge AI and deep learning. To find out how remote on/off can help your application or for help with any edge AI computing or general industrial computing questions, contact CoastIPC at 866-412-6278 or [email protected].