The Universal Serial Bus (USB) reduced cable clutter in personal computers by replacing unique, dedicated I/O connections with simple, interchangeable ones. But USB was not capable of handling most industrial I/O needs — until recently. USB version 3.0 offers features that greatly expand their utility for industrial applications.

With the introduction of USB 3.0 came major improvements in speed, power delivery, and connection over USB’s original specifications. But the most visible change was the introduction of a new connector option — USB Type C (USB-C). Older USB versions use connectors with an asymmetric orientation; they could only plug in one way. And in some cases, the cable required different connectors at the host and peripheral ends. The USB-C connector, however, is symmetric so there is no “up” or “down” to the plug, and the same connector can be used at both ends. Even this simple change helps greatly simplify cable installation.

Speeds to 20 Gbps

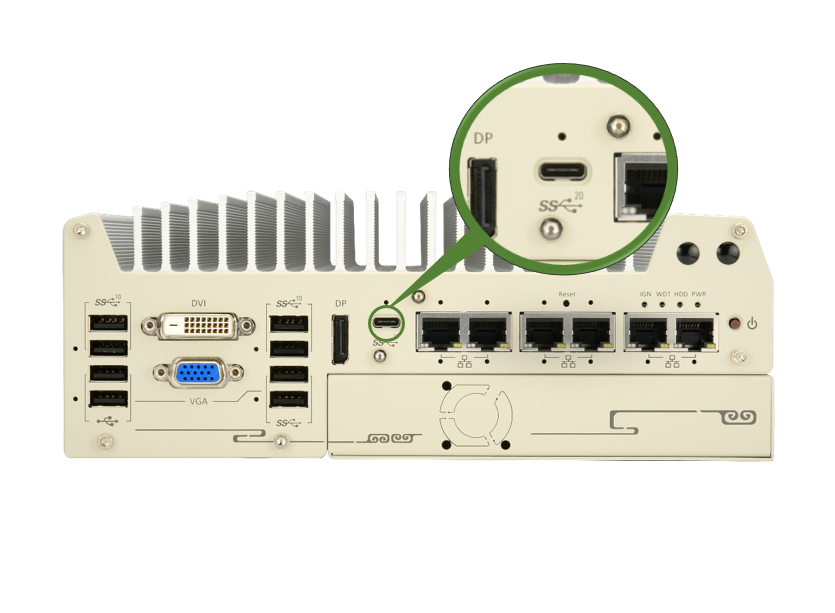

With the new connector option came another improvement to USBs — higher signal speed. While USB 2.0 topped out at 480 Mbps, USB 3.0 raised speed to 5 Gbps. Subsequent versions doubled that to 10 Gbps, and Superspeed variations can reach 20 Gbps. This is enough bandwidth to multiplex audio, video, and data signals onto one cable. Many of these high-speed versions can only use the USB-C connector. In the new Nuvo-9000 series of fanless industrial computers, for example, Neousys Technologies offers a USB 3.2 Gen2x2 type-C port with screw-lock, which delivers 20 Gbps bandwidth for data exchange with external devices. Visit CoastIPC at booth 622 at The Vision Show October 11–13 in Boston, Massachusetts and learn more about the Nuvo-9000 series.

“This simple change helps greatly simplify cable installation.”

Perhaps the most significant improvement for industrial applications, however, is the USB-C Power Delivery feature. Original USB could only deliver 5 V at a little under an ampere. This is enough to power simple industrial peripherals such as sensors and data acquisition modules but not much more. Versions using USB-C can do a great deal more.

With USB-C Power Delivery, the peripheral and host systems negotiate the voltage and current to be provided. The options include 5 V, 9 V, 15 V, and 20 V with output power from 0.5 W to 100 W (20V, 5 A). This extended range greatly increases the possibilities for USB-C industrial peripherals. The camera for a vision system, for instance, can now connect to its host with a single, universal cable supplying power and data channels. Similarly, a portable display and control console for a headless industrial computer could run off a USB-C connection.

Reduce Installation and Inventory

As more and more vendors offer peripherals with USB-C connectors, industrial computer cabling will grow simpler and simpler. A multitude of cable and connector types can be replaced with a single stock item and routing a cable only to realize too late that it was installed backward will become a thing of the past. Further, any USB-C port on the host will work as well as any other, which helps to simplify installation.

One caution for users: The term USB-C refers to the connector type. But because only the higher performing versions of USB use that connector type, USB-C might mistakenly seem to signify the entire USB interface. Only the interface’s version number (3.0, 3.1, etc.) specifies which of the many available performance options a USB-C port provides. Similarly, cables with USB-C connectors can have different power-carrying limits, and some cables provide only power wiring without data-carrying capabilities. When USB-C is in a unit’s description, then, look more closely at the underlying details to ensure the unit will perform as desired.

CoastIPC has the experience and knowledge to help customers navigate the hidden shoals of USB-C implementation. Contact us at [email protected] or 866-412-6278 with questions on USB-C or general industrial computing questions.