Computers used in industrial and commercial settings are often exposed to a variety of environmental factors that can affect system performance and your company’s bottom line. Dust particles, liquids, extreme temperatures, and other factors can all impact the reliability and longevity of an industrial computer.

In this blog post, we'll take a look at the most common environmental factors that can impact your industrial computer and discuss practical solutions on how to reduce negative impacts.

Industrial Computer Environmental Considerations

Considering the ambient environment around the computer and where your device is located are going to determine what environmental considerations we need to protect against when building your computer. Some of the most common questions we discuss with engineers and designers about their projects are:

- How much vibration or shock will your computer experience?

- Is it in a tight enclosure or in an open space?

- Will it operate indoors or outdoors?

- What is the temperature range it will be exposed to in operation?

- Is there ambient airflow around the equipment?

- Is there a risk of particle and liquid exposure?

- Are humidity and condensation levels a concern?

- Are corrosive, harsh chemicals present in your application?

Depending on the application, it is common for industrial PCs to be exposed to grueling conditions. This is why building the right PC configuration for your unique application is key for optimum performance and longevity. Rugged PCs are well-equipped to withstand harsh elements while remaining fully functional and resisting contamination.

Vibration and Shock

There are a few variables to consider when thinking about how vibration and shock will affect your industrial PC. For example, on an autonomous semi-truck, there is going to be constant vibration in the cab because the engine is in close proximity. In other uses, the source of vibration could be from multiple points, constant or variable, and of varying intensity. Not only will the equipment be built to meet the specification, but we will discuss mounting options to keep the installation isolated.

Solutions

Installing rubber mounts with rubber feet and infused grommets can help reduce the amount of vibration that is transferred to the PC. For more extreme cases, like use in off road trucks and military vehicles, CoastIPC can design a custom solution to keep your box secure.

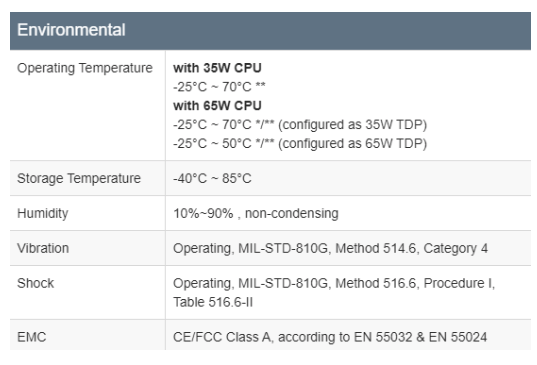

Consider the Nuvo-9000 series from Neousys if you’re looking for a rugged embedded computer that works across many applications. The Nuvo 9000 series is available for purchase online. Contact CoastIPC for guidance with your application.

See the Nuvo-9000 series vibration and shock specifications in the chart below.

Particles and Liquids

The IP Rating (Ingress Protection Rating) is used to classify how well an item blocks out foreign bodies, both solids and liquids. The first digit signifies the ability of solids and airborne particles—dust is a common example—to intrude upon the inner workings of the PC. The second number signifies protection against moisture and liquids. In both cases, the number “1” offers the least protection. In solids, the highest number “6” indicates that the item is dust tight. For liquids, the highest grade “9k” means the item is protected against high pressure, close range, high temperature sprays.

It’s important to know the IP rating because a simple “dust proof” or “waterproof” designation doesn’t give enough detail to ensure an industrial PC is safe in its designated environment. For example, a computer could be labeled “waterproof” because it protects against dripping water. If your facility undergoes a close range spray-down at the end of the day, that won’t be nearly enough to protect it.

At the lower end of recommended protection for an industrial computer, IP65 rated computers are dust tight and no water projected from low pressure jets (6.3mm) from any direction will harm the internal hardware. As we move up to higher grades:

- IP66 Enclosures - Dust proof and able to protect against more powerful water jets (12.5 mm nozzle)

- IP67 Enclosures - Dust proof and able to withstand immersion in up to 1m of water for up to 30 minutes

- IP68—Dust proof and protected from continuous immersion of water or water may enter the container without harmful effects to the internal hardware.

- IP69k—Dust proof and protected against high pressure, high temperature spray downs at close range

- IP69k rated machines offer the maximum level of protection for any computer on the market. We often find these in settings that require sanitation of equipment (including computers), such as the food processing industry.

Solutions for Particles

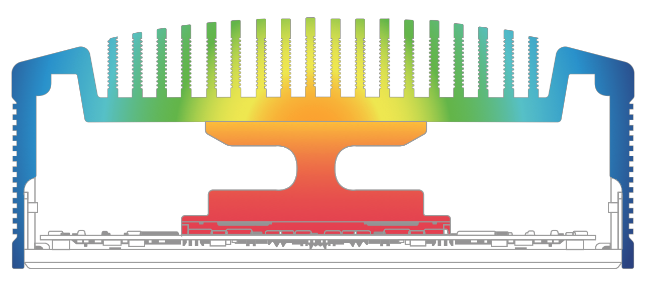

Dust is a common issue that can affect industrial PCs in almost all real world applications, causing them to overheat and lose performance, have a shorter life, or potentially fail. One solution is to use a fanless industrial computer, which utilizes heat sinks to passively cool the internal components.

Industrial applications such as saw mills and mining operations utilize AI computing for critical machine vision and learning applications. Having a PC that computes at full potential avoids overheating and minimizes the risks of slow performance or malfunctioning. Check out the NRU-52S Rugged NVIDIA Jetson Xavier NX Edge AI Computer. Flexible I/O and communication options suggest this is an outstanding controller for indoor/outdoor machines.

Fanless PCs utilize a network of several heat sinks placed all over the board, connecting to the computer’s case which functions as a heatsink.

An advanced option for mitigating dust issues in industrial PCs is using a completely sealed computer, such as the SEMIL-1300. These computers feature completely sealed cases that protect internal components from dust and other contaminants, keeping them clean and functioning optimally for longer periods of time. For lightweight protection consider SUT plugs for unused ports.

Solutions for Liquids

One of the most basic and effective methods for preventing water damage is to use an enclosure that completely seals off the system from external elements. This can include waterproof panels around ports and drives, rubber gaskets to seal off any openings or gaps, or even a full watertight enclosure. For fully submersible solutions, we recommend a rugged PC like the SEMIL-1700 half rack industrial computer or SEMIL-1700GC which is powered by the latest NVIDIA inference cards and designed to withstand the toughest industrial environments. In fact, the SEMIL-1700 series can be submerged in a meter of water for up to 30 minutes, providing a unique and suitable solution for environments with constant water exposure.

Extreme Temperatures

A common question we receive is, “Do I need standard temperature or wide temperature components?”

Wide temperature components are typically - -40 + 85 degrees Celsius

Standard temperature components are typically - -20/0 to 70 degrees Celsius

First, the fanless chassis design is your biggest temperature regulator. A good chassis design will pull heat away from the mounted components. However, the components themselves are also made to withstand different temperature ranges.

If your industrial PC is in a regulated, clean indoor environment, then components will be well regulated with ambient airflow and standard temperature ratings. Industrial standard temperature ranges are wider than commercial (desktop) ratings. Industrial wide components can be significantly more expensive than standard temperature components.

Although high temperatures are more common in industrial settings, low temperatures can be found in many applications, including aviation, food production, or even snow plow trucks. Standard temp components that pass performance testing specifications may be classified and sold as wide temperature components. Although screened wide temperature components work well, CoastIPC offers wide temperature components that are purpose built with rugged design and parts. For critical applications, purpose built wide temperature components offer an advantage.

Solutions

Proper ventilation in and around your computer will minimize heat build up. Make sure the vents and fans are clear of obstructions to increase ambient airflow. Fanless PCs are the most effective option as they can help to dissipate heat more effectively than traditional computer systems without the risk of failed mechanical fans.

Other Hazards

Depending on the environment, other potential hazards, such as oil, chemicals (powder, liquid, and airborne), and gasses can impact performance and shorten equipment life. By understanding that these elements can impact your system’s performance, you can take proactive steps to protect your investment and ensure smooth operations.

If you would like to have a computer built that is best for your specific application or environment, our team of experts is here to help you find the right industrial computer for your needs.