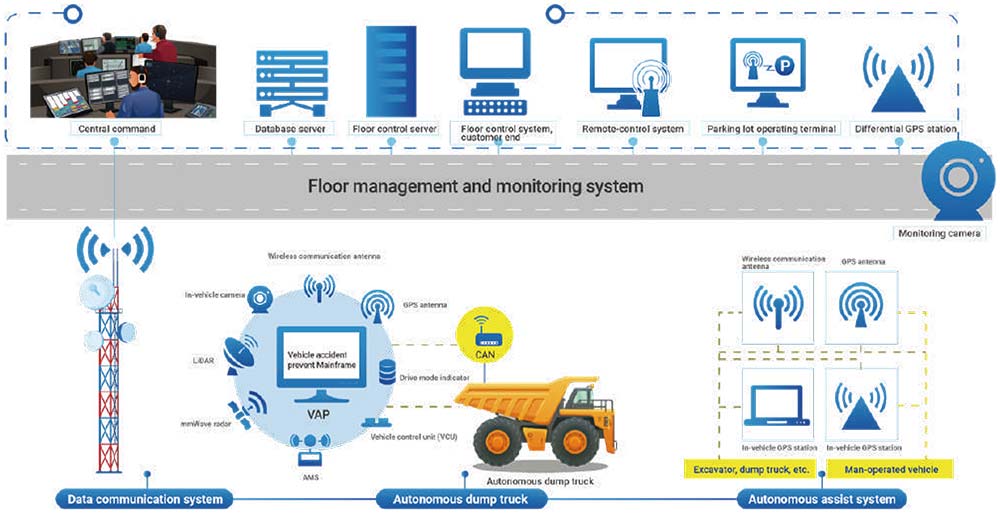

Mining vehicles are integral to modern mining operations, enhancing productivity and efficiency. Today, the application of edge AI technology has ushered in autonomous mining vehicles, yielding three main benefits: (1) Enhancing safety by eliminating human error; (2) Reducing operational costs, including maintenance and labor expenses; and (3) Improving efficiency by deploying autonomous machines capable of tireless 24/7 operation.

Addressing Challenges

Controlling heavy machinery from a distance presents significant challenges, compounded by rugged industrial conditions and remote mining sites subjected to extreme temperatures. Finding controllers with the requisite reliability, machine vision capabilities, AI inference processing power, and efficient boom/arm movement control is no easy feat.

Solutions Implemented

- Enhanced Safety with Autonomous Navigation: Removing human labor from mining vehicle operation significantly enhances safety. Autonomous mining trucks can navigate predefined routes using mid-way checkpoints or GPS guidance, equipped with Lidars and sensors to detect obstacles and hand over control when necessary.

- Cost Reduction with Autonomous Fleet Management: Studies demonstrate that increasing the autonomy of mining truck fleets leads to substantial cost savings over time. Autonomous operations not only save on operator salaries but also minimize vehicle maintenance costs through predictive maintenance enabled by industrial computers and sensors. Additionally, autonomous operation optimizes fuel economy and reduces wear on tires and brakes.

- Efficiency Enhancement and Predictive Maintenance: A larger fleet of autonomous trucks allows for increased operational autonomy, enabling continuous operation without human fatigue constraints. Predictive maintenance, facilitated by industrial computers and sensors, targets small machine issues before they escalate, thus reducing downtime.

Conclusion

Autonomous mining operations, managed remotely from centralized command locations, leverage GPS guidance and minimal human intervention to significantly enhance productivity, efficiency, and worker safety.

Benefits of GPU/In-Vehicle Computers

Environmental

- IP67 water/dustproof GPU computer

- Extreme rugged computers for extra volatile environmental conditions

- Shock and vibration proof for in-vehicle use

- True -25°C up to 70°C wide-temperature operations for harsh, volatile environments

- Patented cassette design for segregating thermal/electrical interference

- Tri-axis tested patented damping bracket to withstand shock and vibration conditions

- Ultra-compact VTC systems to fit into tight spaces

Inference Processing Power

- Supports NVIDIA RTX Series graphics cards (dual card capable)

- Supports NVIDIA Tesla/Quadro inference accelerators

Connectivity/Expandability

- PoE+ connectivity for GigE cameras

- USB3.1 Gen1/ Gen2 connectivity for USB cameras

- Connection ports with screw-lock for rugged connectivity

- WiFi6/WiFi5/5G/4G wireless communication, expansion via mini-PCIe module

Electrical

- Patented SuperCAP UPS to counteract unforeseen power interruptions

- Wide-range DC input

- Configurable intelligent ignition power control

For more information on autonomous operations, please contact our product experts or call us at 866-412-6278.